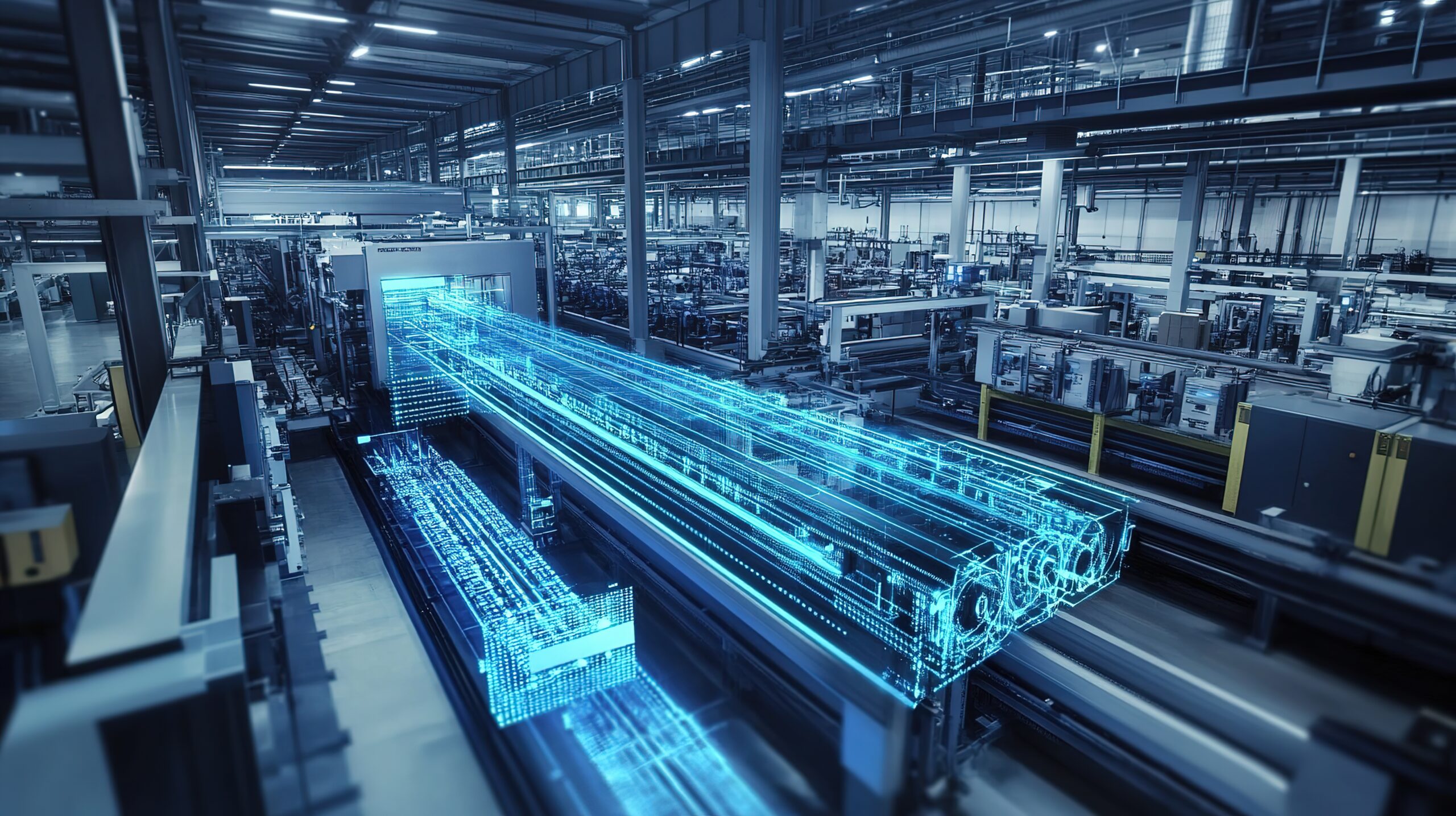

Digital twins vs. executable digital twins: what’s the difference?

The concept of a digital twin, a virtual representation of a physical asset, is nothing new. Engineers have used simulation models for decades to validate designs, reduce risk, and improve performance before anything is built. Executable Digital Twins (xDTs) take that idea much further.

An xDT is a packaged, deployable simulation model that runs outside traditional CAE environments. Instead of living only on an engineer’s workstation, it becomes a usable application that operators, maintenance teams, and decision-makers can interact with, often without any simulation background. This shift enables simulation to move rightward in the lifecycle, from design into:

- Operations.

- Maintenance.

- Optimization.

- Asset retirement and replacement planning.

That’s the real breakthrough.

Why xDTs are ready for prime time in 2026

The Technology Finally Caught Up

For years, digital twins were held back by one simple issue: data availability. Industrial twins require:

- Real-time sensor data.

- Historical operational data.

- Context from engineering models.

Since 2020, accelerated digitalization, especially in manufacturing, has brought that data online. Brownfield assets are now connected. IT and OT systems are converging. Edge computing is standard. Simcenter xDT combines:

- Reduced-order models.

- Physics-based simulation.

- AI and data-driven methods.

The result: fast, reliable, operationally usable twins.

Capturing the Real World, Not the Ideal One.

Design assumptions rarely survive first contact with reality. Assets operate in environments that differ from what engineers originally modeled:

- Variable loads.

- Unexpected temperatures.

- Human behavior.

- Environmental conditions.

xDTs break these silos by continuously aligning the virtual model with real-world behavior.

Predictive Maintenance and System-Wide Optimization.

Traditional maintenance strategies are reactive or time-based. xDTs enable predictive, system-level decision-making:

- Forecast failures before they occur.

- Identify performance bottlenecks.

- Optimize throughput, energy use, and material consumption.

A real-world example is RAMPF, which uses Simcenter Executable Digital Twin to:

- Improve production efficiency.

- Reduce material waste.

- Lower operating costs across entire systems.

xDTs don’t just optimize individual components, they optimize how the entire system behaves under real conditions, including uncertainty and edge cases.

Evergreen Assets and “As-a-Service” Business Models.

Industrial equipment often lasts decades. Hardware may stay the same, but software, models, and insights evolve. xDTs allow organizations to:

- Improve asset performance without replacing equipment.

- Overlay advanced analytics on existing machines.

- Extend asset life while reducing operating cost.

This capability directly enables equipment-as-a-service and digital-twin-as-a-service models. Instead of selling only hardware:

- OEMs can offer uptime guarantees.

- Advanced monitoring services.

- Predictive maintenance packages.

Customers benefit from higher availability and lower risk. Suppliers benefit from recurring revenue and deeper customer relationships.

Training, What-If Scenarios, and Future Design Feedback.

xDTs also change how organizations prepare people, not just machines. Using executable twins combined with VR and modern interfaces, companies can:

- Train workers without physical equipment.

- Simulate emergencies and rare failure scenarios.

- Test procedures before deploying them.

Optimizing a workforce is not based on experience anymore, it’s based on data. Just as important: operational data flows back into engineering. Design teams gain real insight into how products behave in the field, allowing future designs to be:

- More robust.

- Better aligned to real usage.

- Faster to validate.

This closes the loop on the digital thread.

Why Siemens Simcenter Leads the xDT Market.

Executable Digital Twins demand more than simulation software. They require:

- Proven physics.

- Scalable deployment.

- Integration with real operational data.

- Industry experience.

Siemens Simcenter delivers all of those things, plus the engineering services expertise to help organizations deploy xDTs successfully. By combining simulation, AI, IoT data, and edge computing, Siemens enables xDTs that are:

- Accurate.

- Fast.

- Deployable.

- Valuable beyond engineering.

Why Siemens Simcenter xDT Accelerates ROI Faster.

The biggest ROI risk with digital twins isn’t technology, it’s time to value.

Siemens Simcenter Executable Digital Twin reduces that risk by:

- Reusing validated engineering models.

- Supporting reduced-order models for real-time execution.

- Integrating with existing OT, IT, and IoT data sources.

- Scaling from pilot to production without rebuilding models.

This means:

- Faster deployment.

- Lower implementation cost.

- Rapid ROI.

Most organizations see measurable operational impact within the first 6–12 months, not years.

Bottom line.

Executable Digital Twins are no longer experimental. In 2026, they are:

- Operational tools.

- Strategic assets.

- Revenue enablers.

Organizations that adopt xDTs gain earlier insight, fewer surprises, and better decisions across the full lifecycle. Simulation has officially moved beyond design.

Ready to put your xDTs in place?