What Does PLM Stand For?

Every workplace has industry specific acronyms. However, this consistently leads to employees googling and trying to decipher which is correct. If you are working in manufacturing and have heard the term PLM, chances are this is not referring to Private Label Manufacturer or Periodic Limb Movement- but rather Product Lifecycle Management (PLM).

What Does PLM Mean?

PLM is the management of complex product information and workflows. This data is typically stored in a PLM software (e.g., Siemens’ Teamcenter). PLM software dates back to the mid-1980s, when American Motor Company (i.e., the founders of Jeep) needed to beat the odds against their better-funded, more well-known competitors. Today, PLM software is becoming increasingly important in the manufacturing industry. According to Businesswire, the PLM market showed a 9.4% growth from 2017 to 2018 and is anticipated to continue to grow at a CAGR (Compound Annual Growth Rate) of 8.3% reaching $26.7 billion by 2023 in the Americas region alone.

Most companies use PLM software solutions to accelerate time-to-value for their products, eliminate process bottlenecks, improve strategic decisions, and increase the ability for teams to collaborate across job titles. As such, PLM solutions ensure that everyone from conceptual designers to customers are on the same page all while avoiding lengthy data searches or conflicting product information.

Why Is PLM Important?

As the production industry continues to grow, so does the competition. Financial performance is one of the leading distinguishing factors for a company’s success. Therefore, product development continues to become even more crucial. PLM software generally lowers productions costs, accelerates product design timelines, and shortens engineering schedules.

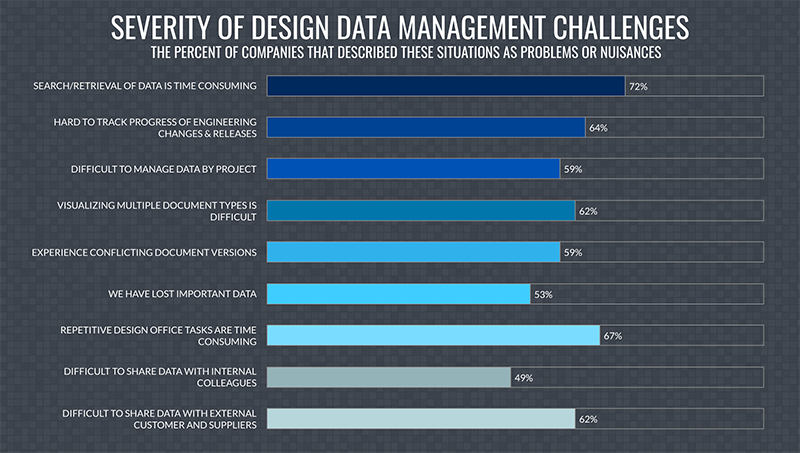

According to Tech-Clarity, 73% of companies find the retrieval of engineering data to be time consuming and 63% find it difficult to track progress of changes and releases. While there are numerous other data management issues affecting the manufacturing industry, it is astounding that 25% of an engineer’s work week is spent either finding product data or trying to decipher the proper storage process. This equates to 8 hours of a 40-hour work week. In other words, if you have 5 engineers on a team, this is equivalent to one of them only working on data management tasks.

For these reasons and many more, companies are prioritizing PLM software implementations and investing in training to ensure their use case is optimized.

To learn more about PLM software, contact the Geometric Solutions team.