Home School for Robots – Program Your Robots Safely From Your Home Office

What is the biggest problem with teach pendant and lead through programming? You can’t do it from home! Robotic Simulation is integral to the manufacturing process. If social distancing is stopping you from physically training your robot, try Process Simulate- an offline programming tool that creates robotic paths and programs at the same time through simulation.

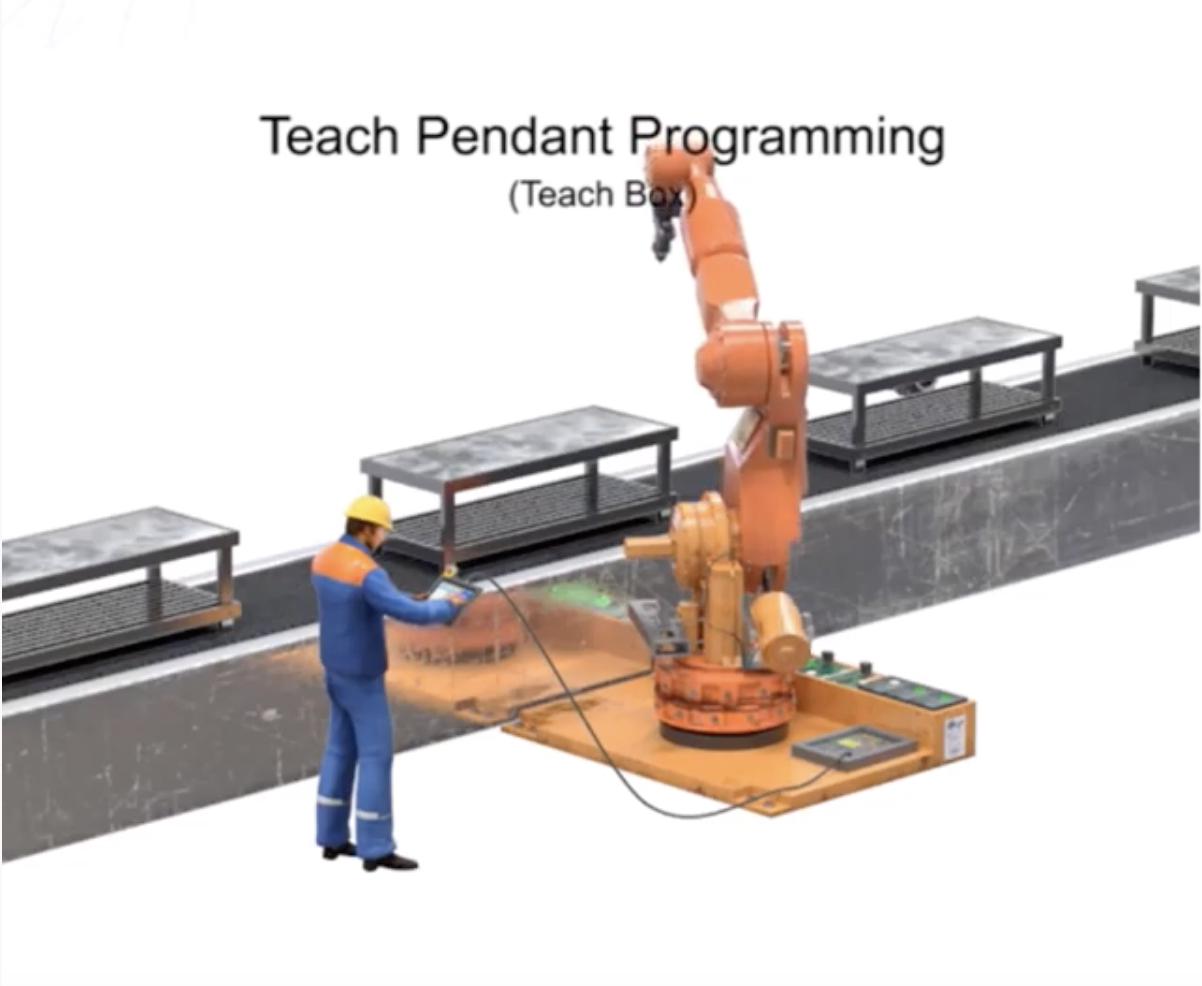

What Is Teach Pendant Programming?

Also known as teach box, Teach Pendant Programming is a manual robot teaching process that occurs on the plant floor after the robot and all other tooling arrive. Due to the need for all necessary robots and tooling, Teach Pendant Programming typically occurs late in the process. During programming, the operator uses a handheld control terminal called a teach pendant that directs the motion of the robot. Movements are controlled by the operator as the robot memorizes trajectories. Once finished, the robot will repeat its learned movements.

What Is Lead Through Programming?

Similar to Teach Box Programming, Lead Through Programming is a manual training process that requires robots and necessary tooling to be physically present on the plant floor. During Lead Through Programming, the operator physically moves the robot, step by step, to teach it the correct trajectories. Once finished, the robot will repeat its learned movements.

Eradicate Start-Up Delays Using Offline Programming (OLP) and Virtual Commissioning

One of the biggest problems with Teach Pendant and Lead Through Programming is that it has to be done on the plant floor with all necessary robots and tolling, leaving robotics training near the end of the production start-up process. This often leads to delays due to incorrect programming and unforeseen collisions. Offline programming allows robotics training to occur earlier in the process and all trajectories can be tested virtually, eliminating costly and time-consuming collisions. Now, you can know if there are design issues before robots and tooling are paid for and all solutions can be quickly tested virtually saving time and money.

Did we mention the best part? This can all be tested from the comfort of your home office with no physical testing needed.

How Can I Learn More About Offline Programming?

Watch Curtis DeSaele, Director of Technology at Geometric Solutions, demonstrate the capabilities of robotic simulation, test a cell-based manufacturing process in minutes, and avoid damages and delays through Virtual Commissioning.