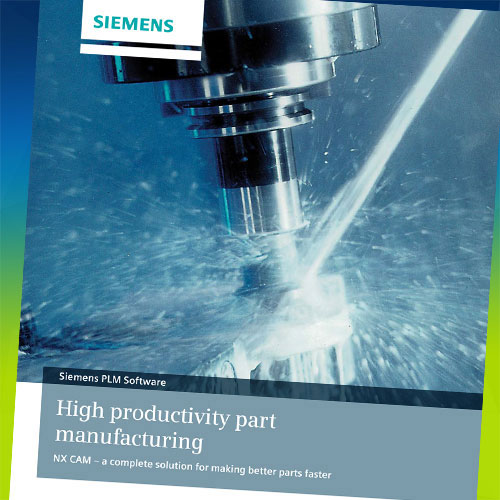

High-Speed Machining in NX CAM

Increase Machining Productivity

Cutting tools get some attention from the high-speed machining (HSM) capabilities in NX CAM. Save machining time by making sure that they consistently perform at their maximum material removal rates. Extend their lives by preventing overloading and damage.

High-Speed Roughing

Maintain high metal removal rates while managing tool loads with high-speed roughing in NX. Safe cutting conditions at high speeds and feeds result from the smooth corners and engagements.

NX reduces machining time automatically, as it tracks the material remaining after each cut and adjusts subsequent tool paths.

Avoiding Over-Embedding the Tool

Based on user-specified criteria, the trochoidal roughing pattern automatically keeps cutting conditions within permissible limits.

Automatic adjustment of the trochoidal loop radii matches stock and part geometry. This prevents the tool-path from “slotting” as the tool becomes fully embedded.

Consistent Finish

Automatically achieve a constant depth of stock in semi-finishing operations and uniform cutting in finishing operations – in both steep and shallow regions – through the addition of intermediate tool paths in Z-Level patterns.

High-Speed Finishing

Produce smooth, flowing patterns that result in fine finishes at high feed rates by using HSM finishing operations, such as the streamline cutting method.

Turn out high-quality surface finishes consistent in steep and shallow areas with precise control over the stepover and depth-of-cut.

Smooth, Continuous Cutting

For non-cutting moves, rely on the software’s various options to enable tangential connections between adjacent cuts. For example, even on irregular shapes you can make smooth helical cuts.

Machining Data Library

Manage and apply proven data to associated tool path operations with NX CAM’s customizable machining database. The appropriate HSM feeds and speeds for a given operation and tool selection are then automatically applied by NX.

Fine-Tuned Output

For high-speed machine controllers NX fine-tunes tool paths. Match methods to the parameters of each task with uniformly distributed points, tangential circular records and non-uniform rational basis spline (NURBS) output options.