Bridging the gap Between AI and automation.

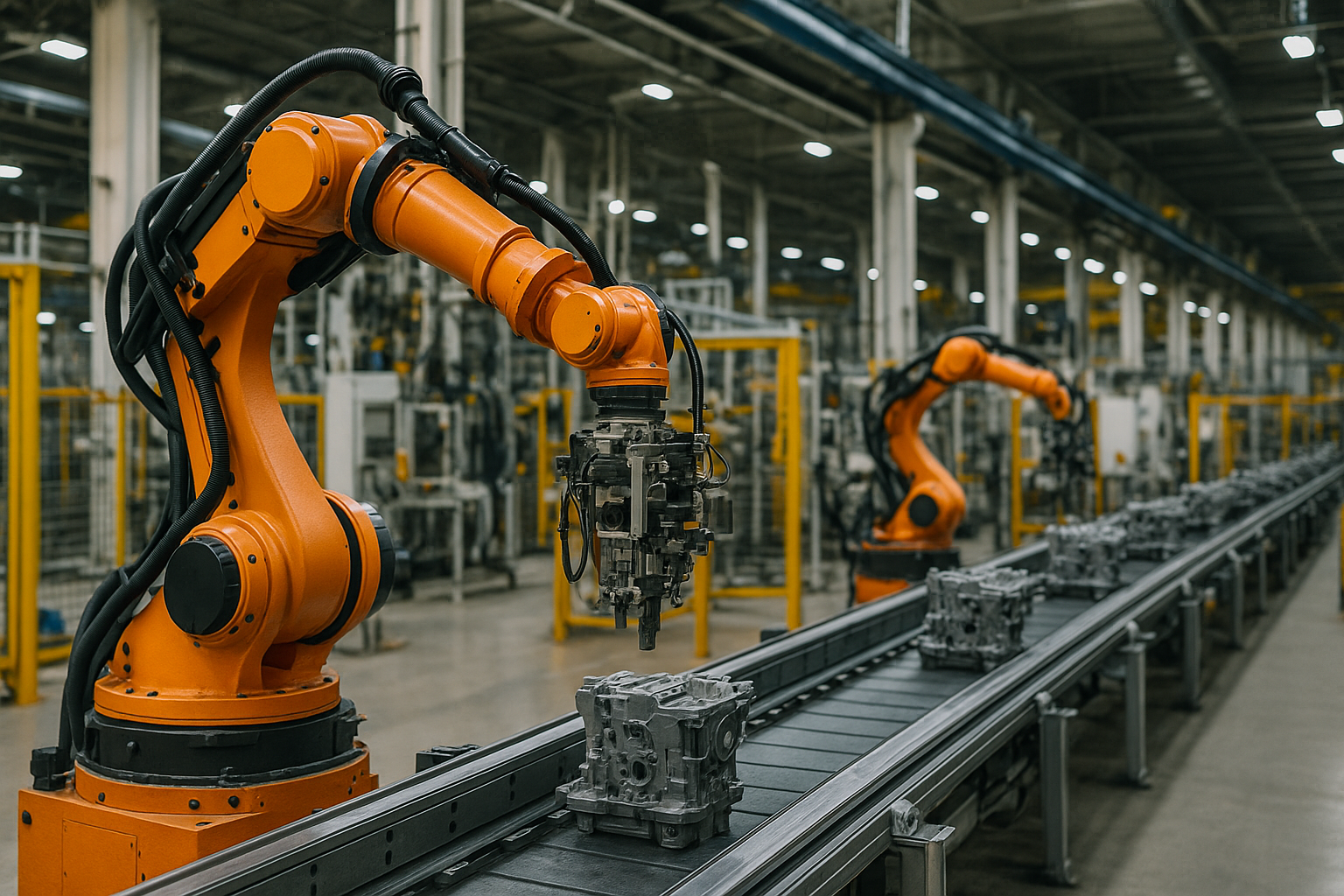

Harnessing the synergy of AI and robotics to overcome automation challenges and unlock smarter factories. The industrial robotics revolution isn’t coming, it’s already here. But for many manufacturers, turning advanced robotics and AI into practical, integrated solutions remains a challenge.

Enter Siemens Tecnomatix. The digital manufacturing suite that helps engineers plan, simulate, and optimize automation systems before a single robot hits the floor. With AI-driven insights, industrial machinery companies can make robots not only faster and more precise, but smarter and more adaptable.

How AI is powering the next generation of industrial machinery.

Traditional robots thrive in controlled environments, repetitive tasks, fixed paths, predictable inputs. But as product complexity increases and demand cycles shorten, manufacturers need flexibility.

AI is the key. Through machine learning and real-time data feedback, Tecnomatix enables robots to adjust to changes dynamically. For example:

- Adaptive path planning lets robots optimize movements on the fly.

- Vision-assisted AI allows robots to identify parts, assess conditions, and make micro-decisions.

- Predictive maintenance algorithms detect wear or anomalies before they lead to downtime.

By integrating these AI-driven capabilities, industrial robots evolve from fixed tools into self-optimizing assets. These assets help to drive faster ROI.

Overcoming the challenges of introducing automation

Automation adoption can feel risky, from high upfront costs to workforce resistance and integration headaches. The good news is Tecnomatix helps you de-risk every step of the process. Here’s how:

- Simulate before you automate: Test robot layouts, cycle times, and workflows virtually to ensure efficiency and safety.

- Validate with digital twins: Model entire production cells in Tecnomatix to optimize human-robot collaboration.

- Upskill your workforce: AI-driven simulation environments double as training tools, helping operators learn safely before implementation.

These practical tools turn automation from a high-stakes investment into a scalable, predictable advantage.

The future potential of AI and automation

We’re moving toward a future where AI, robotics, and simulation work together to create self-correcting, autonomous factories. With Tecnomatix as the backbone, manufacturers can anticipate this future, not react to it.

Imagine robots that schedule their own maintenance, dynamically rebalance workloads, and optimize entire lines without human intervention. It’s not science fiction, it’s the next frontier of smart manufacturing, and it starts with Tecnomatix today.