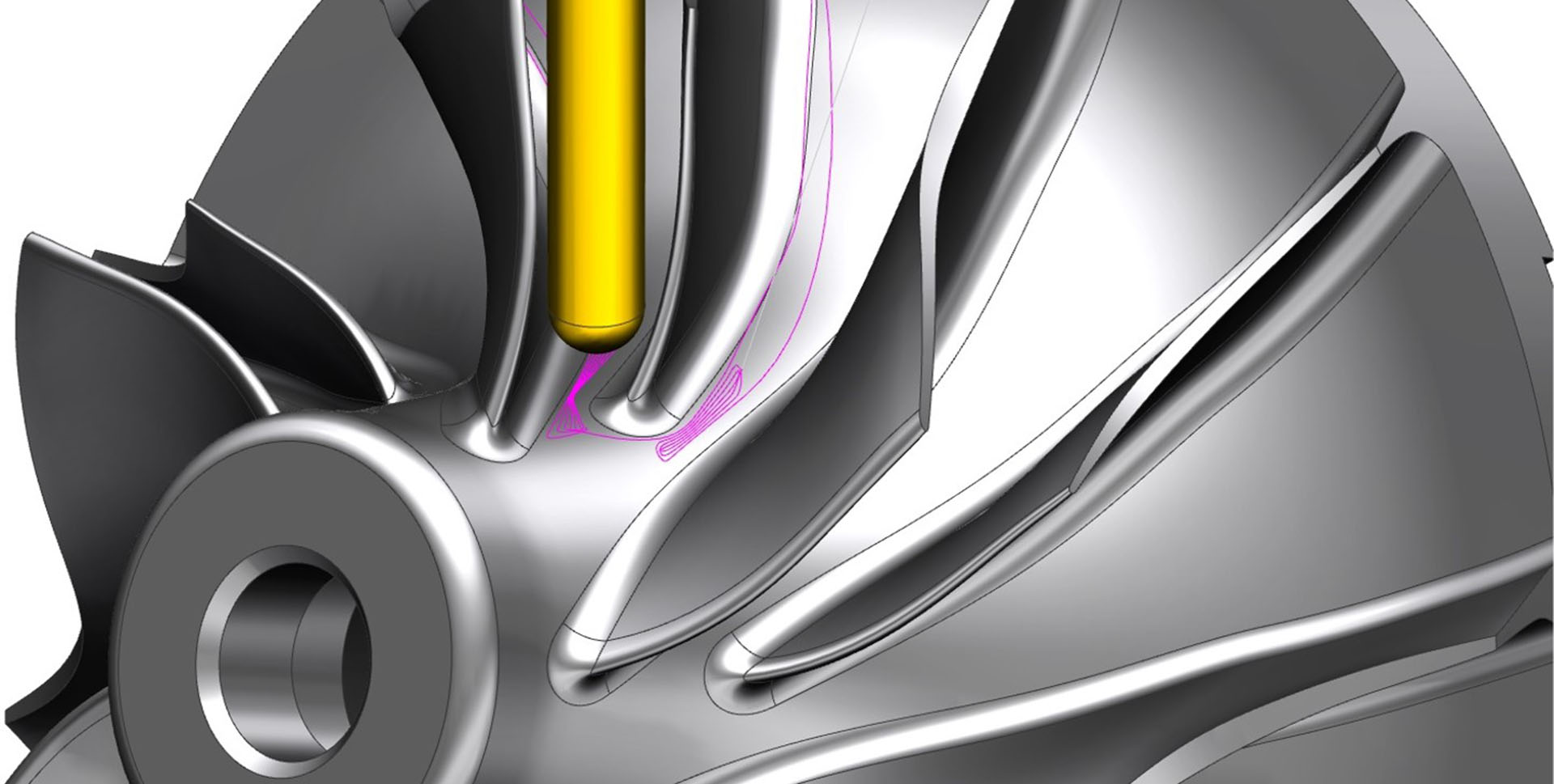

Solid Edge solution’s state-of-the-art techniques deliver accuracy and efficiency while turning out world-class products.

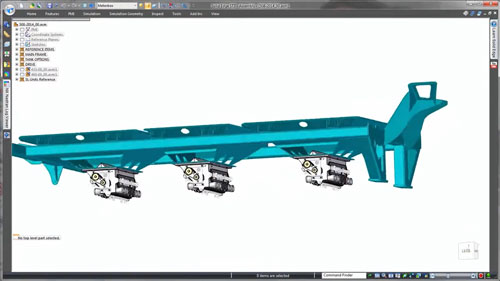

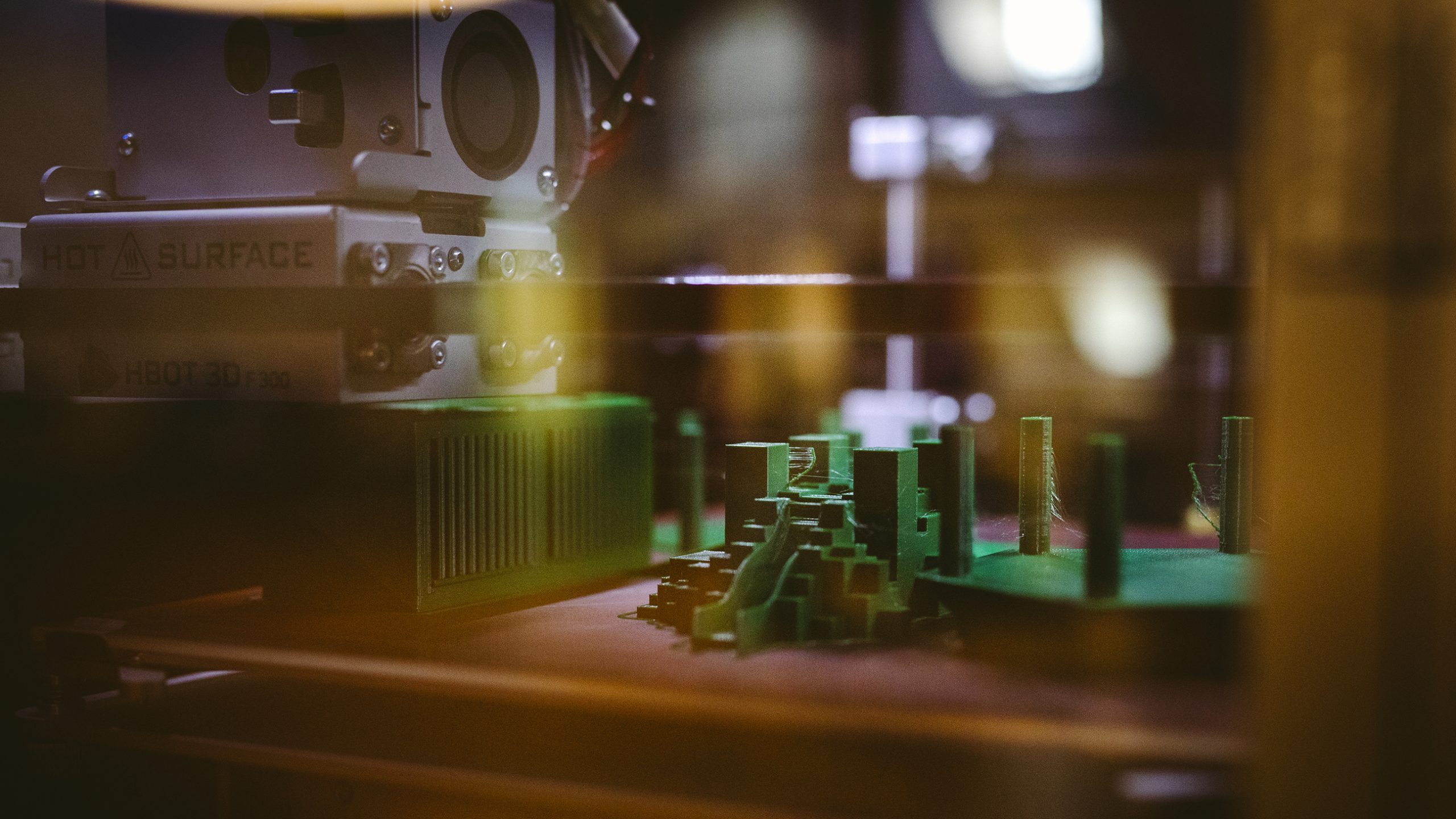

The range of traditional and new manufacturing processes Solid Edge defines and executes include CNC machining, nesting, cutting, bending, molding, welding, assembling, 3D printing and additive manufacturing.

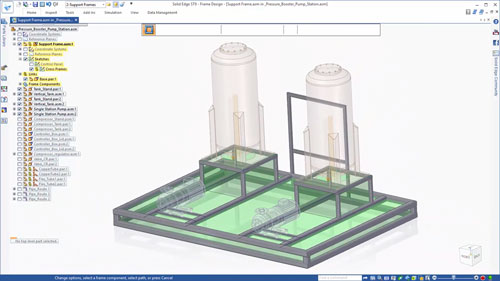

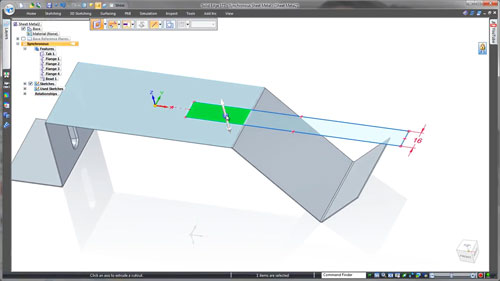

Solid Edge ensures accurate and efficient manufacturing processes as it works directly on your part, sheet metal and assembly models. Updates to design or instruction are easy to implement.

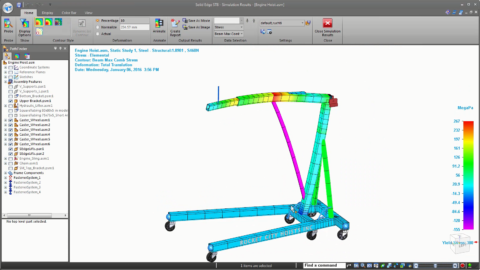

Essential CAD CAM Software

Advanced CAD CAM Techniques

3D Printing and Additive Manufacturing

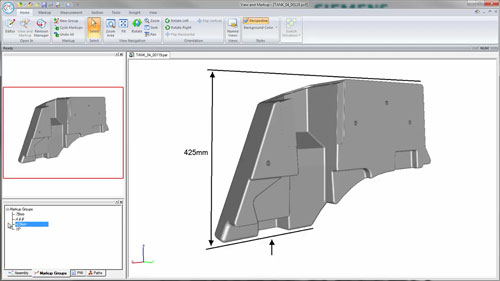

Sheet Metal Manufacturing